On a scorching summer day, flip the fan switch and the blades instantly spin, filling the room with a cool breeze. This effortless, one-second "start-up-airflow" process, however, hides a crucial question: How exactly is electrical energy converted into the power that drives the blades? The answer lies in the principle of electromagnetic induction. Today, we'll break down the workings of this small fan layer by layer.

The core of converting electrical energy into mechanical energy

The bidirectional conversion of electromagnetic induction.To understand fan rotation, you first need to understand electromagnetic induction. It achieves "bidirectional conversion of electricity and magnetism": a current-carrying wire generates a magnetic field (electricity generates magnetism), and the movement of a magnet causes the wire to generate a current (magnetism generates electricity). This is the key to converting electrical energy into mechanical energy.

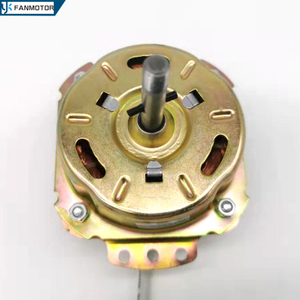

The motor at the heart of a household fan is an example of the application of electromagnetic induction. The motor consists of a fixed "stator" and a rotating "rotor." The stator is wound with multiple coils of wire, while the rotor is a permanent magnet. When the switch is pressed, current flows into the stator windings, generating a strong magnetic field that rotates the rotor's permanent magnets, completing the conversion of electrical energy into kinetic energy.

The four-step process of fan rotation

From power-on to air flow, fan motor operation can be divided into four steps:

Power-on start-up: After closing the switch, AC current flows into the stator winding. The current changes direction 50 times per second, generating a rotating magnetic field in the stator, setting the stage for rotor motion.

Magnetic field drive: After the stator's rotating magnetic field is formed, the rotor's permanent magnets are affected by the magnetic force of "like poles repel, opposite poles attract," and begin to rotate under the alternating attraction and repulsion of the magnetic field.

Speed control: The capacitor stabilizes the current to ensure smooth rotor rotation; the speed regulator adjusts the speed by varying the input current or voltage. For example, a three-speed fan uses three current settings to control the speed.

Power conversion: The rotor rotates the fan shaft, which transmits power to the tilted, streamlined blades. The blades push air backward, creating airflow, converting electrical energy into wind energy within 1-2 seconds.

Operational Differences Between Two Types of Motors

Fan motors on the market are primarily categorized as AC and DC motors. While both operate based on electromagnetic induction, their operating principles differ:

AC Motors: Rotate with the frequency of the AC power

Traditional household fans often use AC motors, which are directly connected to the AC power supply. Changes in the direction of the AC power supply automatically rotate the stator magnetic field, which in turn rotates the rotor. Speed control is achieved by adjusting the magnetic field strength by varying the number of turns in the stator winding. This is cost-effective but offers limited accuracy.

DC Motors: Rely on an Inverter for Speed Control

Modern variable-frequency and remote-controlled fans often use DC motors and require DC power. Because DC power cannot generate a rotating magnetic field, the motor's built-in inverter converts the DC power into "simulated AC" to control the stator magnetic field speed, achieving precise speed control and improving energy efficiency.

The underlying logic of fan speed control

In summer, fan speed adjustment using a knob or remote control shares similar principles, but differs in its methods:

The current or voltage input to the motor determines the rotor speed. The higher the current, the stronger the wind speed.

Knob speed control: Common in older fans, the current is controlled by a variable resistor behind the knob. The larger the resistor, the lower the current, resulting in slower wind speed. This simple design results in high energy consumption.

Remote control speed control: Modern DC fans often use electronic speed controllers. The remote control sends a signal, and the speed controller adjusts the current frequency and magnitude, providing precise speed control, stepless speed regulation, and smooth, energy-saving operation.

Conclusion

Recall the entire process: electric current generates a rotating magnetic field in the stator, which drives the rotor. A speed regulator controls the speed, and the blades ultimately move the air—electromagnetic induction runs the entire fan's operation.

The seemingly complex principles of household appliances are often quite intuitive once disassembled. The essence of a fan is the conversion of electrical energy into rotational force through a magnetic field. The next time you flip on your fan, think about the "electromagnetic magic" hidden within the motor, and share this knowledge with those around you.