Cost-saving Assembly AC Fan Motor Components SKD Kits

RoHS Certified Double Ball Bearing 2 Years Warranty

Brand: YKFANMOTOR | Origin: Guangdong, China | Suitable for: 16/18inch Stand & Table Fans

Product Overview

Our cost-effective AC fan motor solutions include Semi-Knocked Down (SKD) Kits and fully assembled motors, designed exclusively for 16/18-inch stand and table fans. Built with high-quality materials—pure copper windings, double ball bearings, and high-grade silicon steel components—our products deliver reliable performance while helping manufacturers and distributors balance production costs and efficiency.

Key Advantage: SKD kits reduce assembly time by 40% compared to full CKD (Completely Knocked Down) kits, while retaining bulk component sourcing cost benefits.

Ideal For:

Fan manufacturers aiming to balance production costs and efficiency

Large distributors with regional assembly facilities

Brands looking to reduce shipping volume (less volume than fully assembled motors)

Companies with basic assembly capabilities to optimize labor costs

Core Components in SKD Kits

1. High-Strength Motor Housing

Precision-treated for durability, accurate internal dimensions (fits all core parts), no secondary processing needed—ready for direct assembly.

2. Stator Coil with Capacitor

Stator with pure copper windings (optimized for efficiency) pre-integrated with a 1.8μF/450VAC capacitor (customizable). Factory-tested for stable startup/speed control, installable without extra wiring.

3. Rotor with Double Ball Bearings and Shaft

High-precision magnetic core rotor, pre-assembled with double ball bearings and 8mm (customizable) solid C45# steel shaft. Factory-calibrated for concentricity, reducing complex assembly steps.

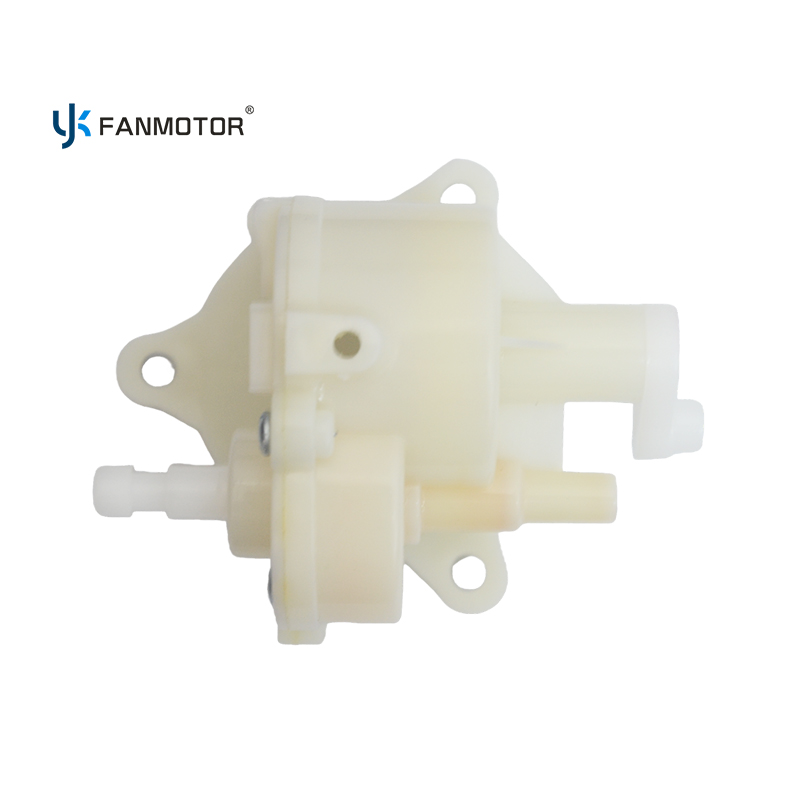

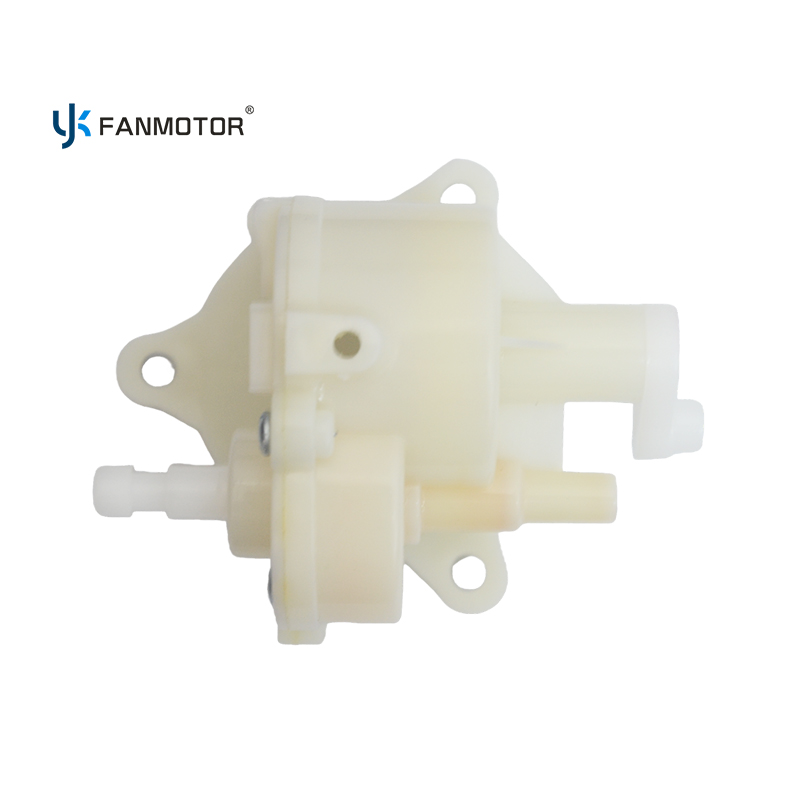

4. Gearbox & Assembly Hardware

Durable gearbox (with matching screws), anti-loosening washers, and insulation gaskets—size-matched for quick final assembly.

Bulk Supply Option

Semi-Knocked Down(SKD) Kits

Fully Assembled Motors

Technical Specifications

| Parameter | Details |

| Power Type | Electric (AC) |

| Bearing Type | Double Ball Bearing |

| Capacitor | 1.8μF/450VAC (customizable) |

| Shaft Diameter | 8mm |

| Stator Size | 71mm |

| Winding Material | Pure Copper Wire |

| Stator Material | High-grade Silicon Steel |

| Rotor Material | Cast Aluminum |

FAQ

| 1 | What equipment is needed to assemble SKD kits? |

| Minimal equipment—basic tools and a simple workstation. We provide detailed assembly guides; most manufacturers can integrate kits into existing lines without major modifications. |

| 2 | Can SKD kit components be customized? |

| Yes!For bulk orders, we offer customization for capacitor specs, winding configurations, shaft diameter, etc. Contact our sales team for MOQ details on custom components. |

| 3 | What quality control is done for SKD components? |

| All components undergo individual testing; pre-assembled modules are 100% inspected for performance. |

| 4 | What shipping options are available for bulk orders? |

| We offer FOB/FCA terms. For SKD kits, we optimize packaging for container shipping to maximize quantity per container. Our logistics team works with major freight forwarders for competitive rates. |