Exhaust fans are essential components in a wide range of industrial, commercial, and residential applications. From improving air quality to controlling temperature and humidity, exhaust fans play a vital role in keeping spaces comfortable and safe. However, like any mechanical device, exhaust fan motors are subject to wear and tear over time, requiring maintenance or replacement to ensure they continue to perform efficiently.

In this complete guide, we’ll take you through the process of replacing and maintaining exhaust fan motors. We’ll cover how to diagnose motor problems, the steps for motor replacement, and best practices for maintenance. Whether you’re managing a commercial HVAC system, maintaining industrial equipment, or ensuring your home exhaust fan works effectively, this guide will provide the essential information you need.

Importance of Exhaust Fan Motors

Exhaust fans are used in a variety of settings, including kitchens, bathrooms, warehouses, factories, and ventilation systems. These fans are responsible for expelling stale air, controlling temperature, removing smoke, fumes, and humidity, and improving overall indoor air quality. The motor within the exhaust fan is the heart of the system, driving the fan blades that move air through the space.

When the motor starts to malfunction, the exhaust fan cannot operate efficiently, potentially causing a buildup of heat, humidity, or harmful gases. Over time, an inefficient motor can also increase energy consumption and lead to higher operating costs. Regular maintenance and timely motor replacement can extend the life of the fan and keep your systems running smoothly.

Common Exhaust Fan Motor Problems

Before diving into the replacement process, it’s essential to identify when the motor is failing or needs maintenance. Here are some of the most common issues that may require motor replacement or servicing:

1. Motor Not Starting

One of the most common problems is when the exhaust fan motor doesn’t start. This issue could stem from electrical problems, a faulty capacitor, or a defective switch.

Potential Causes: Power supply issues, tripped circuit breaker, faulty wiring, or a damaged capacitor.

2. Overheating

Exhaust fan motors can overheat due to excessive use, poor ventilation, or electrical faults. Overheating can lead to permanent motor damage if not addressed.

Potential Causes: Overloading, poor ventilation, worn-out bearings, or electrical problems.

3. Noisy Operation

Excessive noise or unusual sounds from the motor may indicate problems with the motor bearings, fan blades, or improper alignment.

Potential Causes: Worn-out bearings, misaligned fan blades, or loose mounting components.

4. Reduced Airflow

If the fan is running, but airflow is weak, the motor may be underperforming. This can occur if the motor is damaged, overloaded, or if the fan blades are clogged or obstructed.

Potential Causes: Motor malfunction, dirty or obstructed fan blades, or improper motor speed.

5. Vibration

Excessive vibrations in the exhaust fan motor can indicate problems with motor alignment or balance. This could result in inefficient performance or potential damage to the fan assembly.

Potential Causes: Unbalanced fan blades, loose motor mountings, or worn-out bearings.

Steps for Exhaust Fan Motor Replacement

If you’ve diagnosed that the motor needs replacing, follow these steps to ensure a proper and safe replacement.

1. Turn Off Power Supply

Before starting any maintenance or replacement, the most important step is to ensure the system is powered off. Disconnect the fan from the electrical supply to prevent any risk of shock or injury. Use a lockout/tagout procedure if working with industrial systems to prevent accidental re-energization.

2. Remove the Fan Cover

Most exhaust fans are housed within a protective cover. Remove any screws, bolts, or fasteners that hold the fan cover in place. Carefully remove the cover to expose the motor and fan blades.

3. Disconnect the Motor Wiring

With the motor exposed, disconnect the motor’s electrical wiring. Note the connection points for reinstallation, or take a photo of the wiring configuration. If the motor uses a capacitor, disconnect it as well. Be careful not to damage any wires, and make sure to label or document them for easy reattachment.

4. Remove the Fan Blades

If necessary, remove the fan blades from the motor shaft. Most fan blades are connected with screws or set screws. Use a wrench or screwdriver to loosen and remove the fan blades. Make sure to keep any washers, nuts, or screws in a safe place, as you will need them to reinstall the new motor.

5. Unbolt the Old Motor

Once the fan blades are removed, the next step is to unbolt the motor from its housing. Depending on the type of fan, the motor may be mounted with screws, bolts, or brackets. Use the appropriate tools to remove the motor and carefully lift it out of the housing.

6. Prepare the New Motor

Before installing the new motor, make sure it is compatible with the fan system. Check the motor’s specifications, such as voltage, horsepower, and speed, to ensure they match the original motor. If the new motor comes with mounting brackets or other components, attach them to the motor according to the manufacturer’s instructions.

7. Install the New Motor

Position the new motor inside the fan housing and align it with the mounting points. Secure the motor with screws or bolts, ensuring that it is firmly attached to the fan housing. Be sure to check the alignment of the motor shaft with the fan blades to prevent any issues with balance or vibration.

8. Reconnect the Wiring

Using the documentation or photo from earlier, reconnect the electrical wiring to the new motor. Ensure that all connections are secure, and double-check that the wiring matches the manufacturer’s specifications.

9. Reinstall the Fan Blades

Once the motor is connected, reinstall the fan blades onto the motor shaft. Tighten the set screws or bolts to ensure the blades are securely attached. Make sure the blades are aligned properly to prevent imbalances or vibrations.

10. Test the New Motor

Before closing the fan cover, test the new motor to ensure it’s working properly. Turn the power back on and check that the motor is running smoothly, with no unusual noises or vibrations. Measure the motor speed to verify that it is operating at the correct RPM (revolutions per minute) for optimal airflow.

11. Reinstall the Fan Cover

Once you’ve verified that the motor is working correctly, reinstall the fan cover and secure it with screws or fasteners. Clean up the area, remove any tools, and ensure everything is in order before completing the replacement.

Preventive Maintenance for Exhaust Fan Motors

Regular maintenance is essential to extend the lifespan of your exhaust fan motor and ensure it runs efficiently. Here are some key maintenance tips:

1. Clean the Motor and Fan Blades Regularly

Dirt and debris can accumulate on the motor and fan blades, leading to reduced performance and potential overheating. Regularly clean the fan blades with a damp cloth or a vacuum cleaner. Also, ensure that the motor is free from dust or grime buildup, as this can affect its operation and efficiency.

2. Check the Bearings

The bearings in the motor are responsible for reducing friction and ensuring smooth rotation of the fan blades. Regularly inspect the bearings for wear and tear. If you hear grinding noises or notice excessive vibrations, the bearings may need to be lubricated or replaced.

3. Inspect the Wiring and Electrical Connections

Check the wiring and electrical connections periodically for signs of wear, corrosion, or loose connections. Tighten any loose wires and ensure that the motor is receiving the correct voltage. Faulty wiring can lead to electrical issues or even motor failure.

4. Monitor Motor Temperature

Excessive heat is one of the leading causes of motor failure. Regularly check the motor temperature to ensure it’s within the recommended operating range. If the motor is overheating, inspect the system for proper ventilation and airflow. Overloading the motor can also cause it to run hot, so make sure the motor is correctly sized for the application.

5. Lubricate the Motor

Many exhaust fan motors have bearings that require periodic lubrication to prevent excessive wear. Follow the manufacturer’s guidelines for lubrication frequency and use the correct type of lubricant. Proper lubrication can reduce friction, prevent overheating, and extend the motor’s lifespan.

6. Check for Imbalance and Vibration

Unbalanced fan blades or misaligned motors can lead to vibrations, which can cause excessive wear on the motor. Regularly inspect the fan blades for any signs of damage or imbalance, and ensure that the motor is properly aligned with the fan shaft.

When to Replace the Motor

Even with proper maintenance, motors will eventually reach the end of their lifespan. Some signs that it’s time to replace your exhaust fan motor include:

Frequent breakdowns or malfunctions

Persistent overheating or electrical issues

Excessive noise or vibration that cannot be resolved

Reduced airflow or performance, even after maintenance

Inability to find replacement parts

If any of these signs are present, it’s time to consider replacing the motor to avoid system failure and minimize downtime.

Conclusion

Replacing or maintaining your exhaust fan motor is crucial for keeping your systems running efficiently and extending the lifespan of your equipment. By understanding the common problems that affect fan motors, following proper replacement procedures, and performing regular maintenance, you can ensure that your fan motor continues to operate smoothly and reliably.

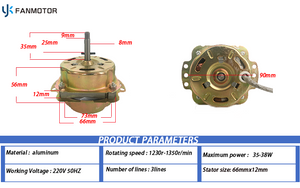

For high-quality exhaust fan motors and reliable components, Guangzhou Yuexun Electric Appliance Co., Ltd. offers a range of durable and efficient fan motors designed to meet the needs of various industrial and commercial applications. Their products are engineered for performance and longevity, ensuring that your fan system remains in optimal condition for years to come.