Product Description

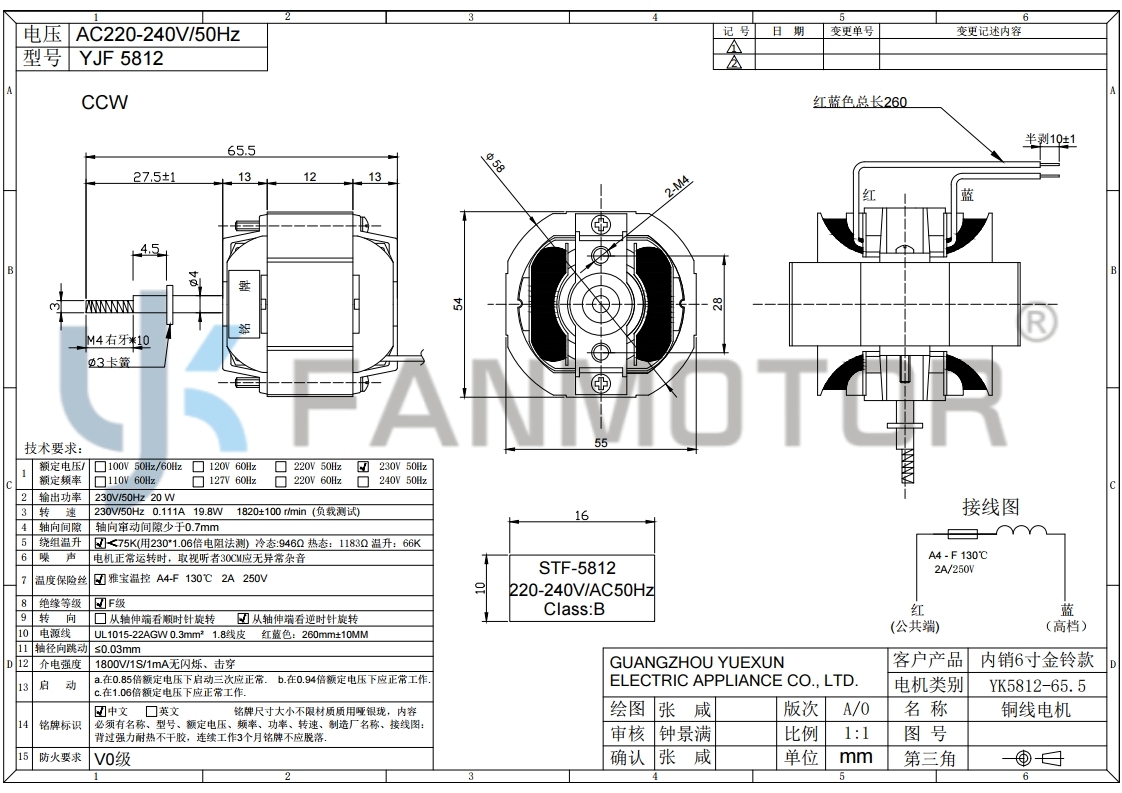

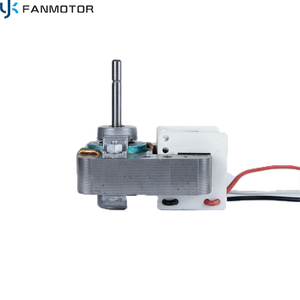

The YK5812-65.5 6-inch exhaust fan motor provides compact, high-efficiency ventilation with aluminum windings for reduced weight and energy consumption. Operating at 220-240V/50Hz and 20W power, it delivers rapid airflow via 18,200±100 RPM rotation (CCW direction), ideal for swift smoke, steam, or heat removal. Class F insulation ensures thermal reliability with <75K temperature rise during prolonged use. Designed for demanding environments, its durable construction supports kitchen exhaust systems, bathroom humidity control, and workshop air circulation. The motor combines quiet operation with low maintenance, prioritizing both performance and longevity in confined spaces.

Product Advantages

1. High-Speed Aluminum Ventilation

The YK5812-65.5 6-inch exhaust fan motor integrates lightweight aluminum windings with a precision-engineered 18,200±100 RPM high-speed rotor, enabling rapid air exchange in confined areas. This configuration optimizes smoke, moisture, and fume extraction efficiency while maintaining low power consumption (20W). Its construction reduces heat retention and enhances durability,achieving 15-20% faster ventilation than standard models,ideal for kitchens, bathrooms, or workshops.The motor’s counter-clockwise (CCW) rotation . Compatible with 220-240V/50Hz systems, it balances energy efficiency with robust performance for small to medium spaces requiring quick air renewal.

2. Industrial-Grade Durability

Engineered for demanding environments, the YK5812-65.5 exhaust fan motor features Class F insulation and a thermal design limiting temperature rise to <75K, ensuring reliability in high-humidity or warm settings. Built for continuous 24/7 operation, this 6-inch motor reduces downtime in commercial kitchens, industrial workshops, or bathrooms. The advanced insulation system also prevents electrical degradation, extending service life by up to 30% compared to Class B counterparts, while maintaining compliance with industrial safety standards.

3. Compact & Quiet Design

Optimized for space-constrained installations, the YK5812-65.5 6-inch exhaust fan motor combines a compact frame with advanced vibration-dampening technology, operating at <55 dB for minimal noise disruption. Its CCW rotation and aerodynamic blade design maximize airflow (up to 120 CFM) without bulk, fitting seamlessly into residential or light commercial ventilation systems. The aluminum windings and balanced rotor assembly reduce mechanical hum, making it ideal for noise-sensitive areas like apartments, hotel bathrooms, or office kitchens.

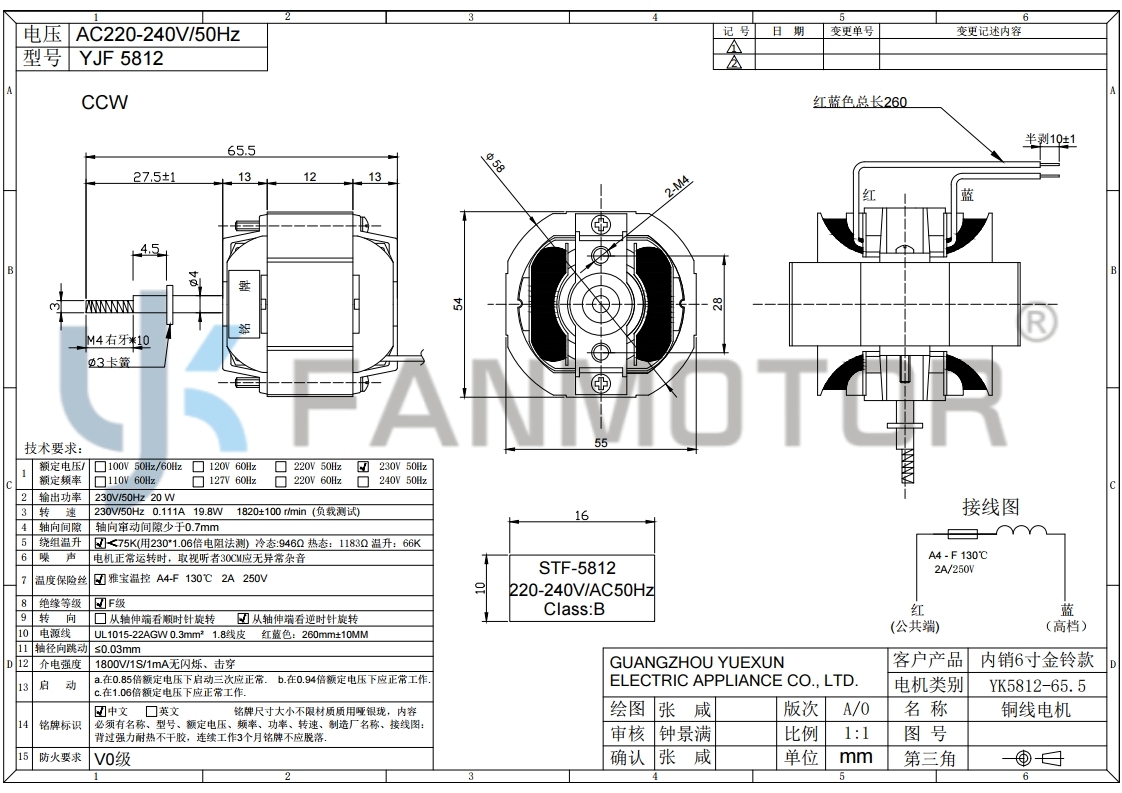

Product Parameters

Product name | 6 inch Exhuast fan motor |

Model | YK5812-65.5 |

Wire | Aluminum wire |

Voltage | AC220-240V/50Hz |

Power | 20W |

RPM | 18200±100r/min |

Insulation class | Class F |

Rotation direction | CCW |

Temperature rise | <75K |

Product Application

Our exhaust fan motor is an asynchronous motor based on single-phase AC power. It has the characteristics of simple structure, low cost and easy maintenance. It is widely used in small and medium power and single-phase power supply scenarios.

1. Home kitchen: exhaust cooking fumes to keep the kitchen air fresh.

2. Home bathroom: remove moisture and odor to maintain a dry and clean bathroom environment.

3. Small restaurants: exhaust a small amount of fumes and odors generated during cooking to improve the air in the store.

4. Office/shop bathroom: continuous ventilation to deal with odor problems in high-frequency use scenarios.

5. Small warehouse/storage room: ventilation and dehumidification to prevent goods from getting damp and moldy.

6. Small industrial workshop/laboratory: local exhaust of dust, hot air or a small amount of chemical volatile gases to help improve the working environment.