I. Product Overview & Core Advantages

Our 71×14mm Series 220V Fan Motors are specifically engineered for household and commercial ventilation equipment box fans. Offering superior performance, extended operational life, and highly competitive pricing, they represent the best choice for enhancing your product quality and reliability.

Core Advantages:

High Efficiency & Energy Saving:

Ultra-Quiet Operation:

Durable & Long-Lasting:

Constructed from carefully selected, high-quality materials, the motor boasts a lifespan exceeding 5,000 working hours, guaranteeing stable and reliable long-term performance.

Controlled Temperature Rise:

Flexible Customization:

Key parameters such as shaft length, voltage, speed, and installation method can be customized precisely to meet your specific product design requirements.

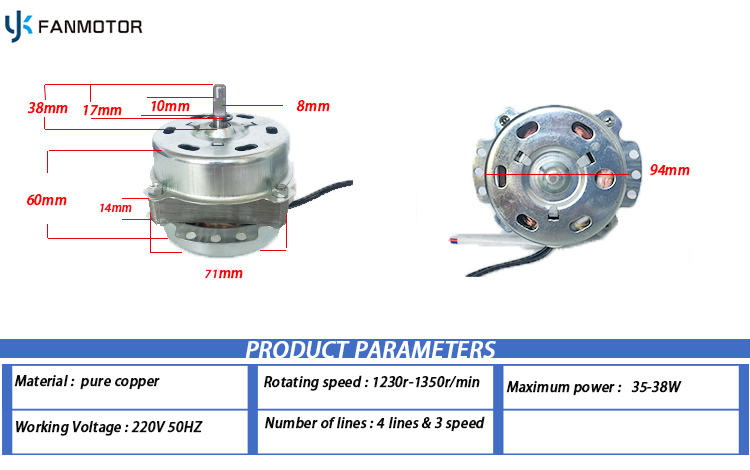

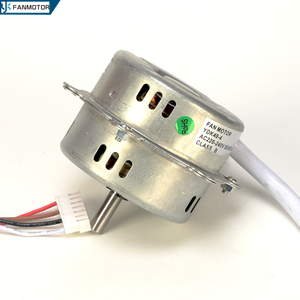

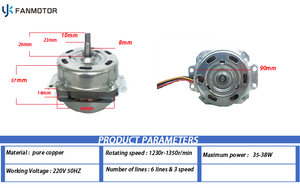

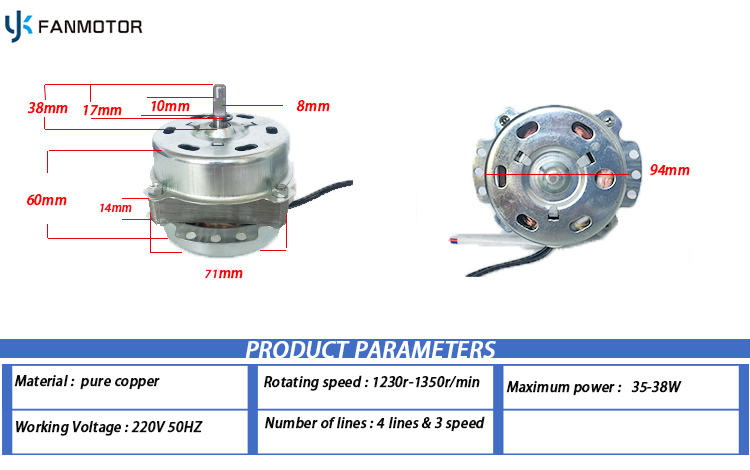

II. Technical Parameters (Specifications)

| Parameter Name | 71×14 Standard Model | Notes / Customization |

| Model | YKF-7114 | 71 Series Capacitor Start-up AC Motor |

| Rated Voltage | AC 220V / 110V | Customizable for Global Voltage Standards |

| Rated Frequency | 50Hz / 60Hz | Universal Frequency Input |

| Input Power | 35-38W | Actual Power is Load-Dependent & Adjustable |

| Rated Speed | 1230-1350 RPM | Customizable |

| Insulation Class | B or F | High-level insulation for safety and reliability |

| Speed | 3 speed | Flexible control of wind speed |

| Bearing Type | Oil-impregnated bushing / Ball bearing | Selected based on required lifespan and budget |

| Material | Pure copper wire winding, high-quality silicon steel sheet | Guarantees high efficiency and low heat generation |

III. Application Areas

The 71×14 series electric fan motors, with their stability and versatility, are widely used for household commercial cooling box fans

IV. Manufacturing & Factory Advantages

Choosing us means partnering with a company committed to quality, efficiency, and reliability:

28 Years of Expertise: Over 28 years focused on fan motor R&D and manufacturing, providing a mature technical system and quality management experience.

International Certification: ISO Quality Management System certified; products comply with major global standards like CE, CCC, and RoHS.

Strict Quality Control: Implements two-time 100% quality inspection system; every single motor undergoes fully automated testing before leaving the factory.

Strong R&D Team: Possesses rapid response and customized design capabilities, assisting customers in optimizing motor performance for new product requirements.

One-Stop Service: Provides a seamless solution from design and prototyping through production to logistics, simplifying your procurement process.

V. Packaging and Delivery

Standard Packaging: Professional thickened five-layer corrugated cardboard boxes.

Packaging Quantity: 20/40/100 units per box (determined by motor size and customer specifications).

Special Requirements: Custom-printed cartons and palletized packaging services are available upon request.

Lead Time: Sample orders: 3-5 business days; Bulk orders: 15-25 days (depending on order quantity and complexity).

VI. Frequently Asked Questions (FAQ)

Q1: What is your Minimum Order Quantity (MOQ)?

The standard MOQ for standard models is typically 1000 units. We offer more flexible policies for first-time customers; please contact our sales team for details.

Q2: How can I obtain samples for testing?

Samples (maximum 2 units) can be provided free of charge; however, shipping costs are borne by the customer. Samples are dispatched within 3 working days after shipping fees are received.

Q3: What is the motor warranty period?

We offer a one-year standard warranty on all ac electric motors shipped. During the warranty period, we provide free replacement or repair for non-human-caused quality issues.

Q4: Do you accept OEM/ODM customization?

Yes, absolutely. Our robust engineering team is fully capable of providing customized OEM and ODM services based on your technical drawings and precise performance requirements.

Q5: What are your accepted payment methods?

We typically accept T/T (Telegraphic Transfer), requiring a 30% deposit and the remaining 70% balance due before shipment. Other methods (such as L/C) are negotiable.