1: What is the difference between a gearless traction machine and a traditional traction machine?

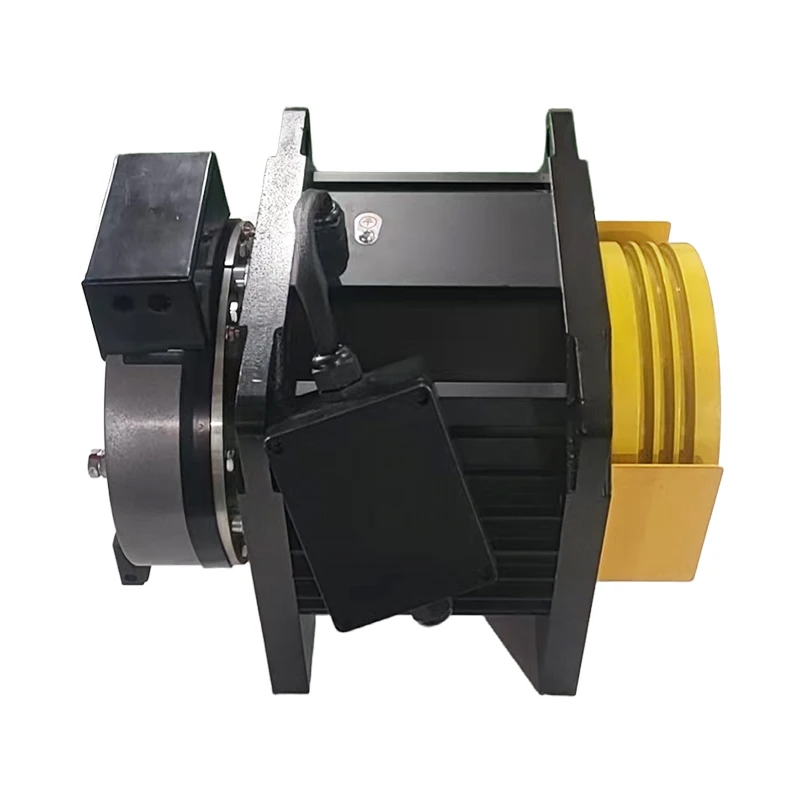

—The gearless traction machine eliminates the reduction gearbox and is directly driven by the motor, which is more efficient, less noisy and requires less maintenance.

2: How long is the maintenance cycle?

— Routine maintenance is performed every 2 years, mainly checking the bearings and brake system, and no lubricating oil needs to be replaced.

3: Does it support the transformation of old elevators?

— Yes, but the original shaft size and power supply conditions need to be evaluated. It is recommended to contact an engineer for on-site survey.

4: How long is the product life?

—15-20 years under normal use.

5: Is it suitable for machine room-less elevators?

— Yes, the gearless traction machine is designed for machine room-less elevators, with a small size and no need for additional load-bearing structures.

6: What is the price range?

—Depending on the model and configuration, the price range is US$800-1500, and customized quotations are supported.