Industrial Electric Stand Pedestal Wall Floor Fan Motor

1. Brief details:

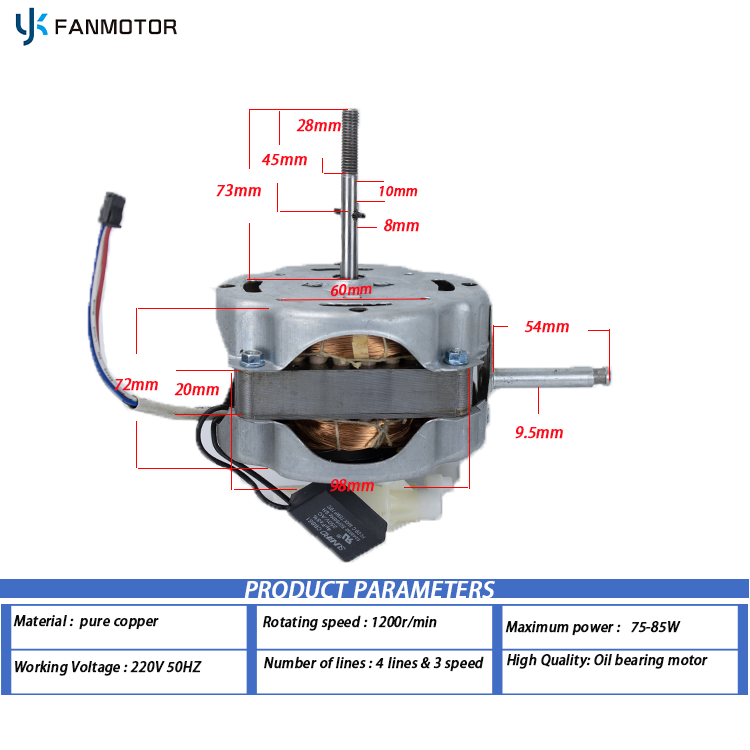

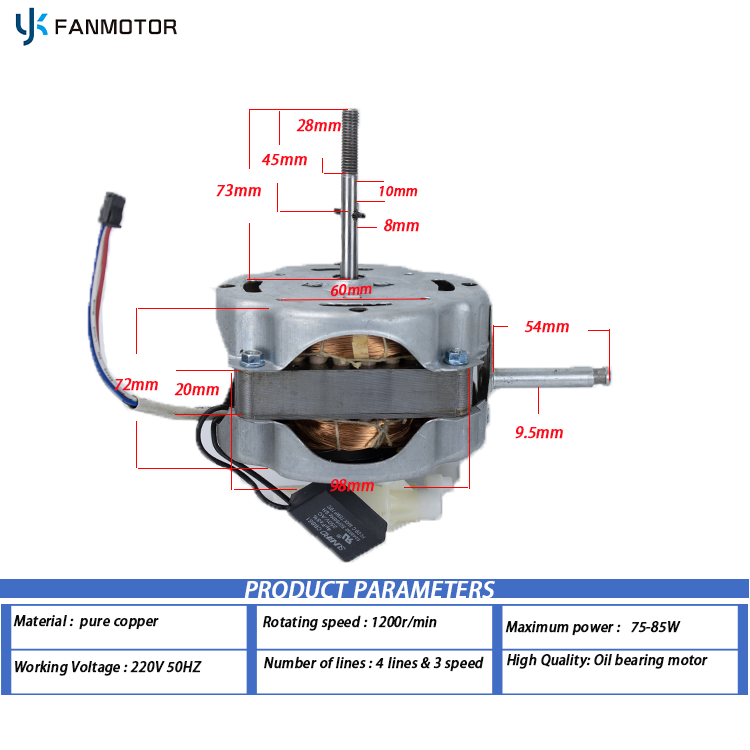

Stator size: 98*20mm (stator size can be customerized)

Material of the wire winding: pure copper (Can be decided by customers)

Packing: 10pcs/ctn, with standard exporting carton

Lead time: 20-25 days

Free design and free samples.

2. Detailed pictures of Industrial Electric Stand Pedestal Wall Floor Fan Motor:

Application:Industrial Stand Pedestal Wall Floor Fan

a. Fan motor cover punched from high pressure machine, tidy and net. Thickness is 1mm.

b. Fine and clean copper wire winding, and packed well in the stator.

c. Industrial fan motor connector pole diameter: 9.5mm.

d. Fan blade shaft diameter: 8mm.

e. Screw diameter: 5mm, length: 24mm with nuts.

f. Power cord is screwed by 1mm thickness rubber band.

3. Packings: For motor & parts, we use standarded exporting packing cartons with foam and packing belts.

4. Delivery and container loading:

We have professional team for container loading, to make sure the container loading net and clean. At the same time , make sure the safty of the fan motors.

5. We provide services for purchasing other parts for electric fan motor and fans for all customers. To load together in our factory, and lower the cost of the time and money of all customers and friends!

6. Production workshop

7.Certificate column

FAQ:

This is a copy of catalog.

Can I buy samples placing orders?

Yes.Please feel free to contact us.

Our products have sold in a number of areas abroad. They are very popular with the users there

When will make delivery ?

Delivery Time

-Sample Order: 3-7 days after receipt of the full payment.

-Stock Order: 7-15days after receipt of the full payment

-OEM Order: 15-25days after receipt of the deposit.