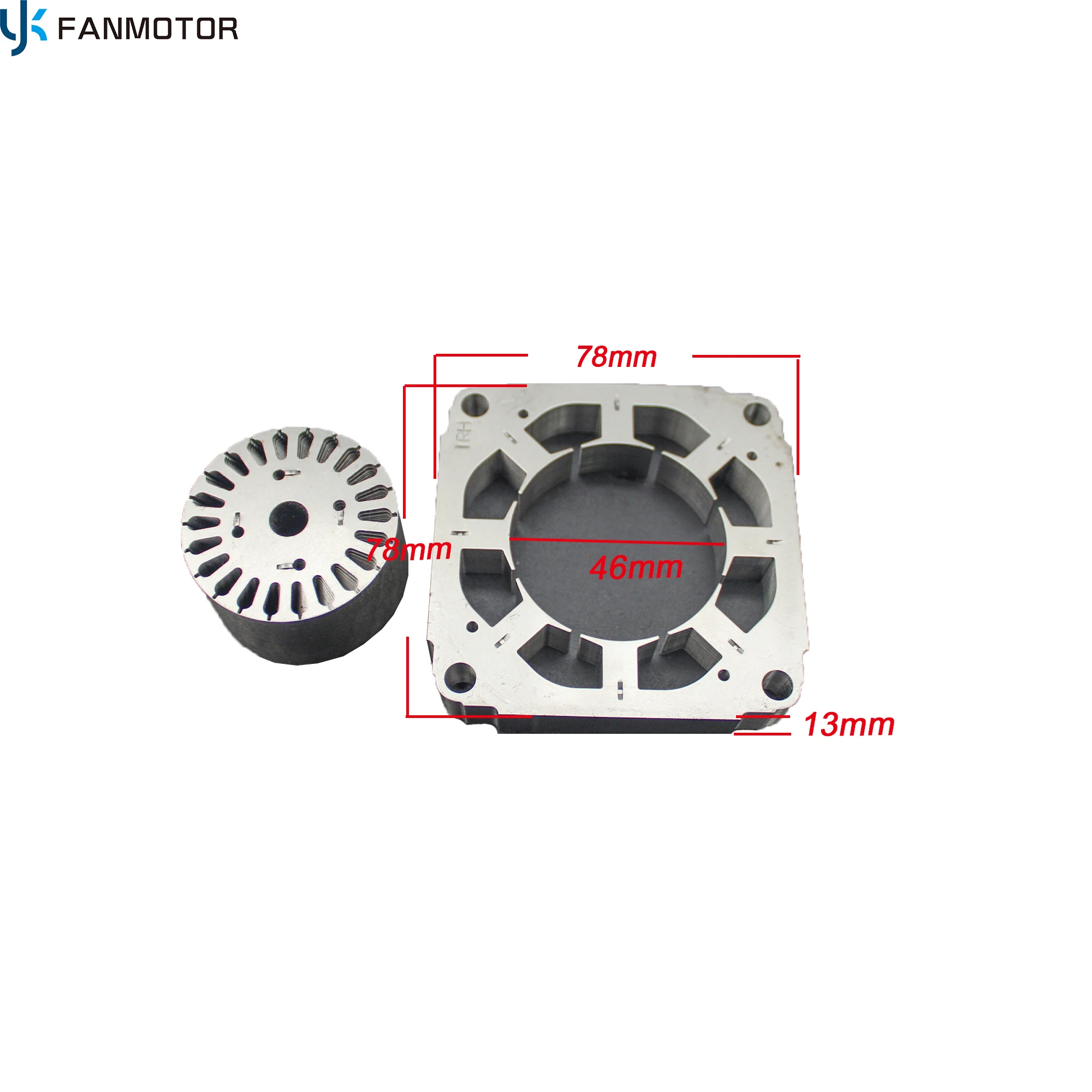

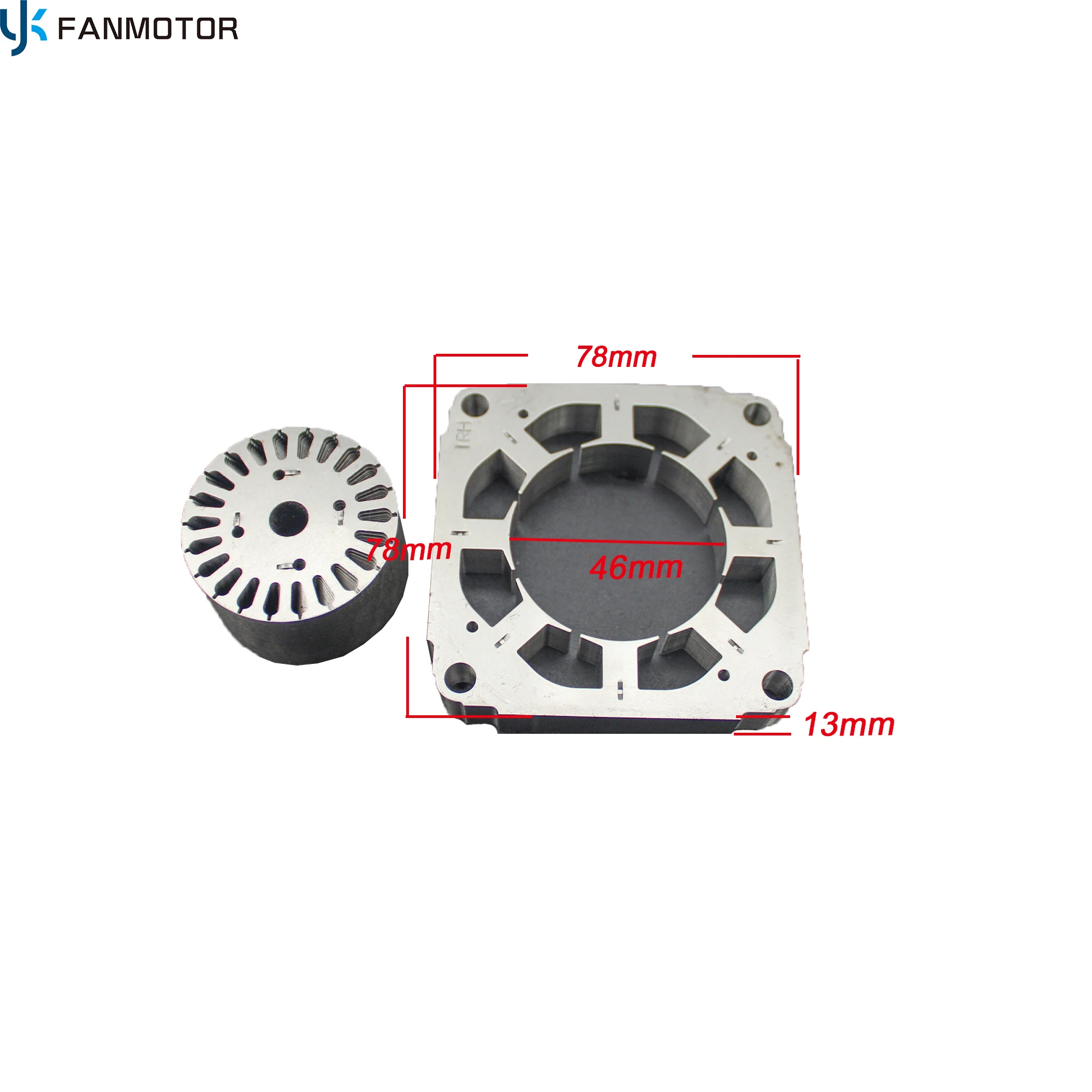

Outer diameter of stator | 78*78mm |

Inner diameter of stator | 46mm |

Stator thickness | 13mm |

Number of slots | 8/customizable |

The difference between new products and traditional products

| New products | Traditional products |

| The inner winding copper wire method effectively,protects the copper wire and prevents performance degradation due to wear | Traditional winding methods can easily lead to copper wire wear and performance degradation |

| low cost | high cost |

| The stator size will be slightly larger | The stator size is slightly smaller |

Main Products

Packaging & Shipping

The packaging method generally uses foam,carton, nylon bag.

if you have a designated packaging method please communicate with us.

Company Information

Guangzhou Yuexun Electric Co., Ltd. is newly estanblished head office only for fan motors in 2017. It is based on the family company in GuangDong. It focus on the OEM and ODM of all kinds of home used and business used fan motors, such as: stand fan motor, table fan motor, wall fan motor, floor fan motor, exhaust fan motor, box fan motor, industrial fan motor, floor fan motor,shaded pole motor fan parts ect.

For production: We have 1800 squre meters, 68 workers with more than average 8 years experiences in fan motor production. 8000pcs fan motors is our daily production capacity.

For technology backup: We have 4 technicians work for all our customers to solve all problems, making samples and making samples.

For trading services: We have professional foreign marketing and sales team with experiences in fan motor industrial, can confirm with customers in first time. No need to wait.

For aftersales services: We provide aftersales services for every order. Will solve all problems within 48 hours. Guangzhou Yuexun Electric Co., Ltd. is not only services you in produciton, but also in technology, trading, and aftersales services. Welcome all friends and customers to contact us for any help in fan motor industrial!