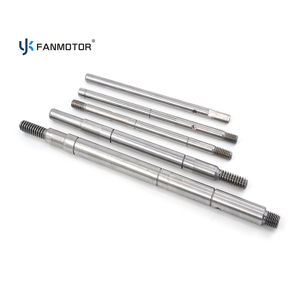

Product Overview

The Custom C45 Steel Fan Motor Shaft is a critical component for AC electric fans (stand/table/pedestal fans). Crafted from premium C45 steel, it delivers exceptional durability, precise torque transmission, and seamless assembly—all compliant with ISO & RoHS standards. Ideal for B2B manufacturers seeking cost-effective, high-quality motor parts to elevate end-product performance.

Key Features & Advantages

✅ Superior Material & Durability

Premium C45 steel (HRC 55-60 hardness)

Resists wear, deformation, and high-speed operation stress

✅ Ultra-Precision Performance

Diameter tolerance ±0.005mm; TIR ≤0.01mm

Reduces vibration, ensures quiet operation, and improves energy efficiency

✅ Multi-Functional Design

Thread (M4/M5/M6): Secure fan blade/end cover assembly

Circlip Groove: Fixes bearings/components stably

Pin Hole: Prevents part displacement during rotation

Knurling: Enhances torque transmission & rotor core locking

✅ Rust Protection & Quality Assurance

Why Choose Yuexun?

Our 13,000㎡ manufacturing facility—your reliable source for custom motor shafts

1. Factory-Direct B2B Supplier

2. Flexible Customization (Core Strength)

Tailor diameter (8mm-15mm+), length (100mm-240mm+), threads, grooves, or surface treatments

Fast sample delivery (3-7 working days) + OEM/ODM support

3. Stable Supply & On-Time Delivery

4. Global Compliance & Support

Standard Specifications

Specification

| Details |

| Diameters | 8mm, 10mm, 12mm, 15mm (customizable) |

| Lengths | 100mm - 240mm (customizable) |

| Thread Specs | M4, M5, M6 (customizable) |

| Tolerance Diameter | ±0.005mm; TIR ≤0.01mm |

| Surface Hardness | HRC 55-60 |

| Surface Treatment | Anti-rust oil (standard); Zinc plating (optional) |

| Certifications | ISO, RoHS |

| Warranty | 2 years |

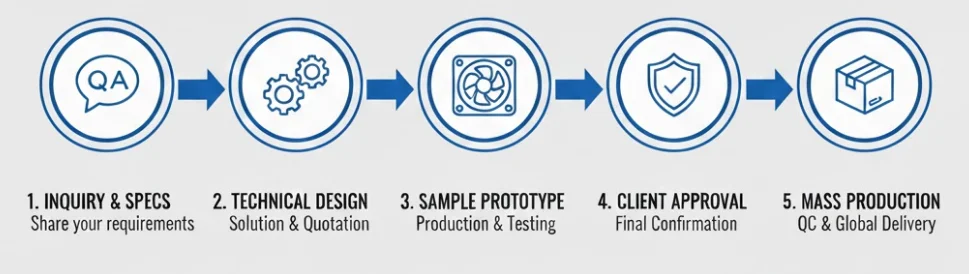

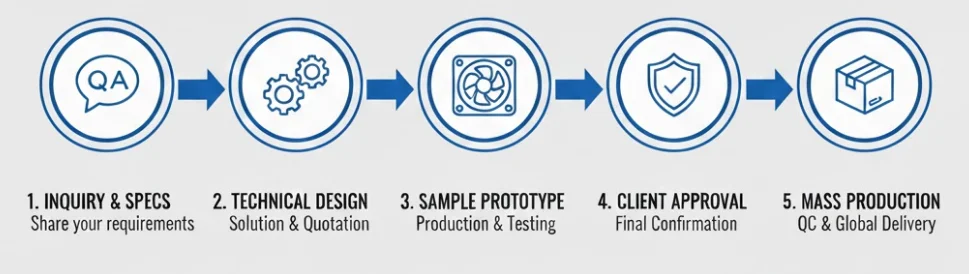

Simple Customization Process

Inquiry: Share your specs (size, structure, quantity)

Design: We provide technical drawings for confirmation

Sample: Test prototype (3-7 working days)

Production: Bulk manufacturing with strict QC

Delivery: Global shipping to your warehouse

FAQ

Q: Do you provide sample?

A: Yes,we provide free sample for test.You only need to pay the shipping fee.

Q: Can you meet EU/US import standards?

A: Fully ISO/RoHS certified; we provide necessary documentation for customs clearance.

Q: What's the payment term for bulk orders?

A: T/T (30% deposit, 70% before shipment) or L/C for large orders.

Q: How do you ensure consistent quality?

A: Raw material inspection → in-process testing → finished product precision/hardness/rust resistance checks.

Ready to customize your C45 fan motor shaft?