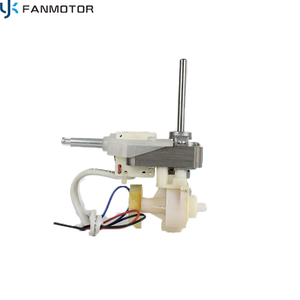

Application:Oscillating Pedestal/Retro Pedestal/Stand/Table/Misting fan

Quick Details:

Quick Details:

| After-sales Service Provided | Free spare parts |

| Warranty | 3 years |

| Type | Fan Parts |

| Application | Household |

| Power Source | Electric |

| Place of Origin | Guangdong, China |

| Brand Name | YK fan motor |

| Model Number | FS-1680 |

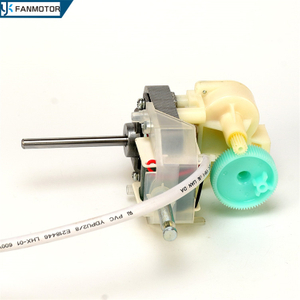

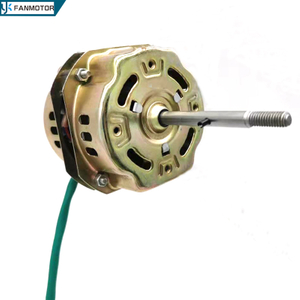

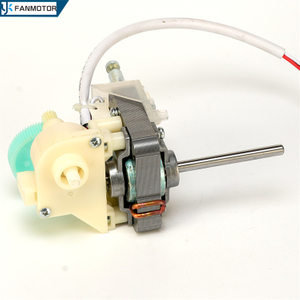

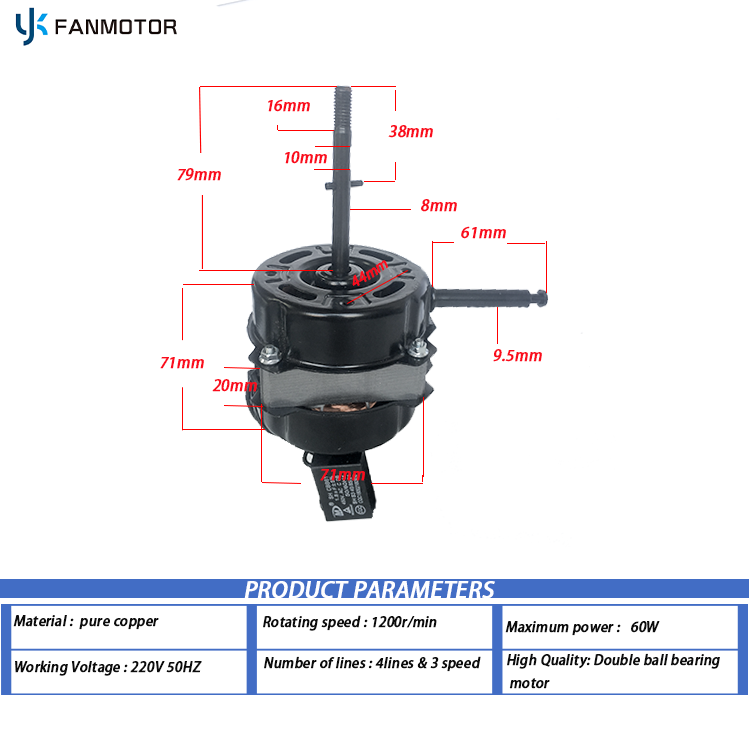

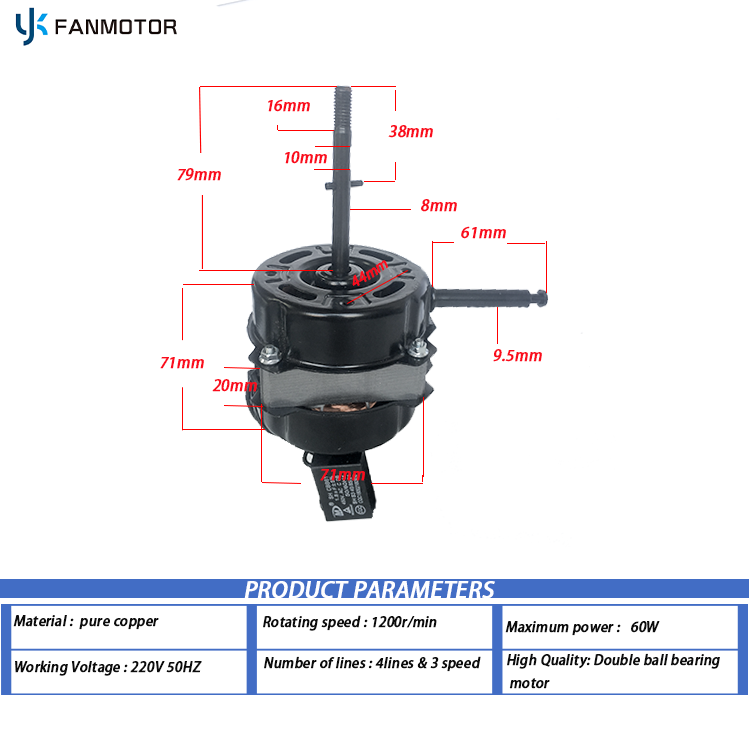

| Item | 16 inch 18 inch double ball bearing stand fan motor |

| Stator size | 71*20mm |

| Wire winding material | pure copper wire winding (can be aluminum, alu&copper) |

| Suitable for | 16 inch 18 inch high quality stand fan |

| Voltage | 220V/50HZ, 110V/60HZ |

| Power | 60W |

| Capacitor | 1.8uf, 450VAC |

| Supply Ability | 240000 Piece/Pieces per Month |

| Packaging Details | 20PCS/CTN |

| Port | NANSHA/GUANGZHOUI/SHENZHEN

|

Lead Time :

Quantity(Pieces) | 1 - 500 | 501 - 1000 | >1000 |

Est. Time(days) | 20 | 25 | To be negotiated |

Product Characteristics and services

1. Long life span of more than 10 years.

2. Super quiet for the motor running.

3. Can be customized and free samples within 3 days for our customers.

4. Pure copper wire winding with high quality double ball bearing.

5. Strong technology backup and quick contacting

6. Quotation within 6 hours.

7. Free samples within 3 days.

8. Professional foreign trade team work in fan motor industrial from the year of 2011.

Data Sheet:

item | 16 inch 18 inch double ball bearing stand fan motor |

stator size | 71*20mm |

wire winding material | pure copper wire winding (can be aluminum, alu&copper) |

suitable for | 16 inch 18 inch high quality stand fan |

Voltage | 220V/50HZ, 110V/60HZ |

Power | 60W |

Capacitor | 1.8uf, 450VAC |

3. Packings: For motor & parts, we use standarded exporting packing cartons with foam and packing belts.

4. Delivery and container loading:

We have professional team for container loading, to make sure the container loading net and clean. At the same time , make sure the safty of the fan motors.

5. We provide services for purchasing other parts for electric fan motor and fans for all customers. To load together in our factory, and lower the cost of the time and money of all customers and friends!

6. Production workshop

7.Certificate column

FAQ:

This is a copy of catalog.

Can I buy samples placing orders?

Yes.Please feel free to contact us.

Our products have sold in a number of areas abroad. They are very popular with the users there

When will make delivery ?

Delivery Time

-Sample Order: 3-7 days after receipt of the full payment.

-Stock Order: 7-15days after receipt of the full payment

-OEM Order: 15-25days after receipt of the deposit.

How To Order ?

Step 1, please tell us what model and quantity you need;

Step 2, then we will make a PI for you to confirm the order details;

Step 3, when we confirmed everything, can arrange the payment;

Step 4, finally we deliver the goods within the stipulated time.

Quick Details:

Quick Details: